Extraction process in FLAVEKO Trade

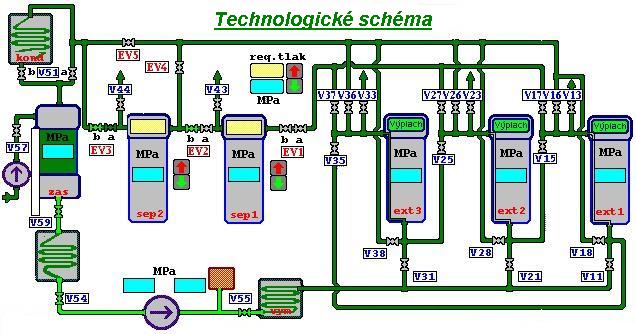

Our commertial extraction unit includes 3 extractors, 2 separators, condenser, CO₂ tank, high-pressure circulating pump and a heater. All process-side parts are made of stainless steel. The three extractors are operated in a semicontinuous way i.e. that two extractors are always on-stream while the third is being emptied and refilled. Maximum operating pressure is 30 MPa and max. operating temperature is 70 ⁰C.

Liquid carbon dioxide from the tank is by the circulating pump compressed to operating pressure and then heated to operating temperature in the heater. Supercritical carbon dioxide from the heater passes through the extractors where it becomes saturated with extract. It is then fed through expansion valves to the separators where the extract precipitates due to a sharp drop in pressure. The gaseous extract free carbon dioxide from the separators is then liquified in the condenser and fed back to the tank. This completes the cycle and the liquid carbon dioxide is again compressed, heated and in supercritical state fed to the extractors.